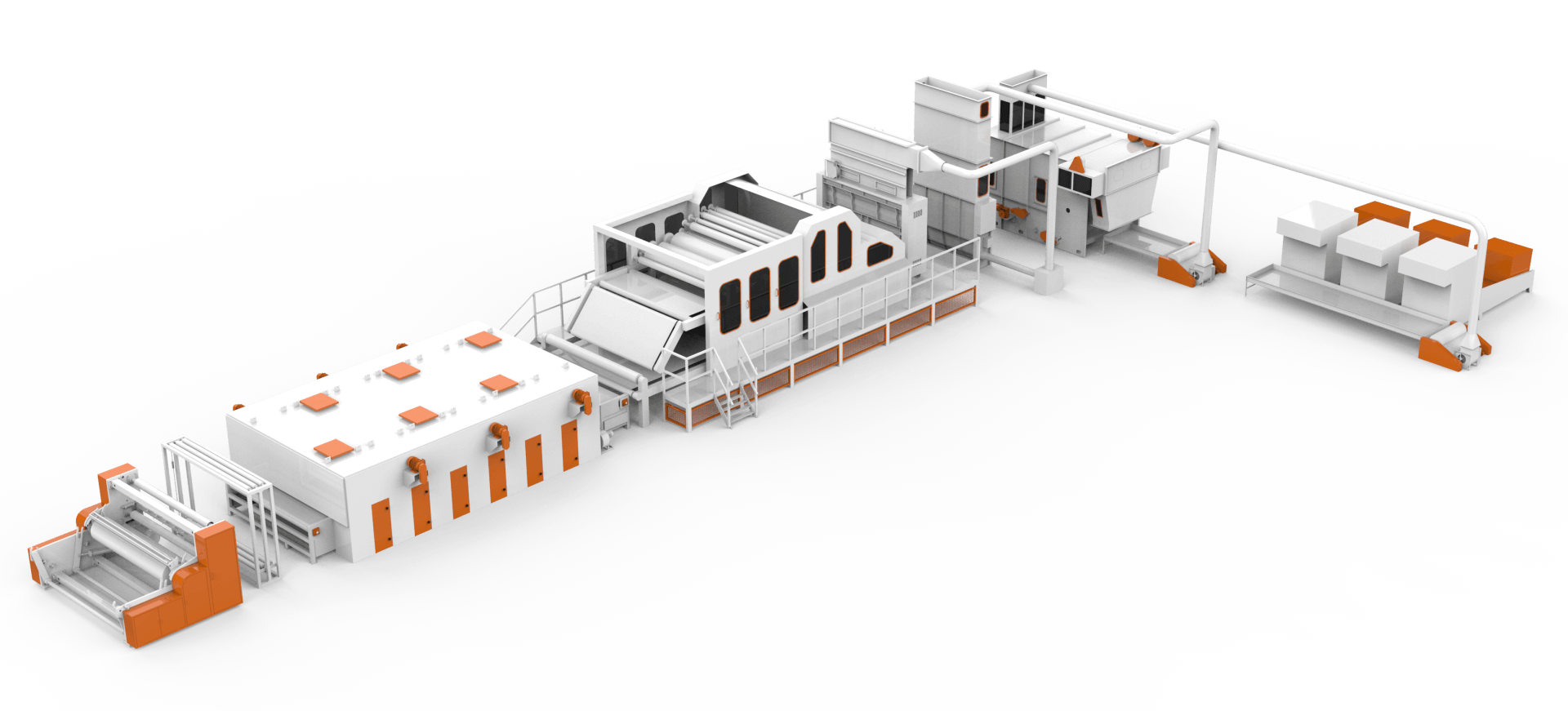

The hot air through bonding machine applies heat and pressure to the nonwoven fabric, allowing fibers to fuse together and form a cohesive structure. This process enhances the fabric’s softness, breathability, and absorbency, making it suitable for various applications such as hygiene products, medical supplies, and filtration materials.

AZX has more than ten years of R&D, production and sales experience.

Over 300 AZX non woven production lines have been already installed worldwide.

AZX has a 10,000 square meter workshop.

AZX controls over 20 core technologies and technical patents of non woven machines.

AZX non woven machines have already been provided to over 30 countries and regions.

AZX remote assistance system can help you find and deal with problems in time.

If you know what you want to produce but are unsure which technology you need, we will be happy to advise you. We will guide you to the right component or line.

Nonwoven fabric provides a soft and breathable surface, ensuring comfort and reducing skin irritation.

Non-woven fabric provides high absorbency and leak protection, ensuring user comfort and dignity.

Its high absorbency and softness enhance comfort and hygiene for users.

Non-woven fabric offers high absorbency and protection for bedridden patients or pets.

It is producing material for applications that safely protect medical staff and patients.

We’ve got you covered with a free non-woven machines catalog.