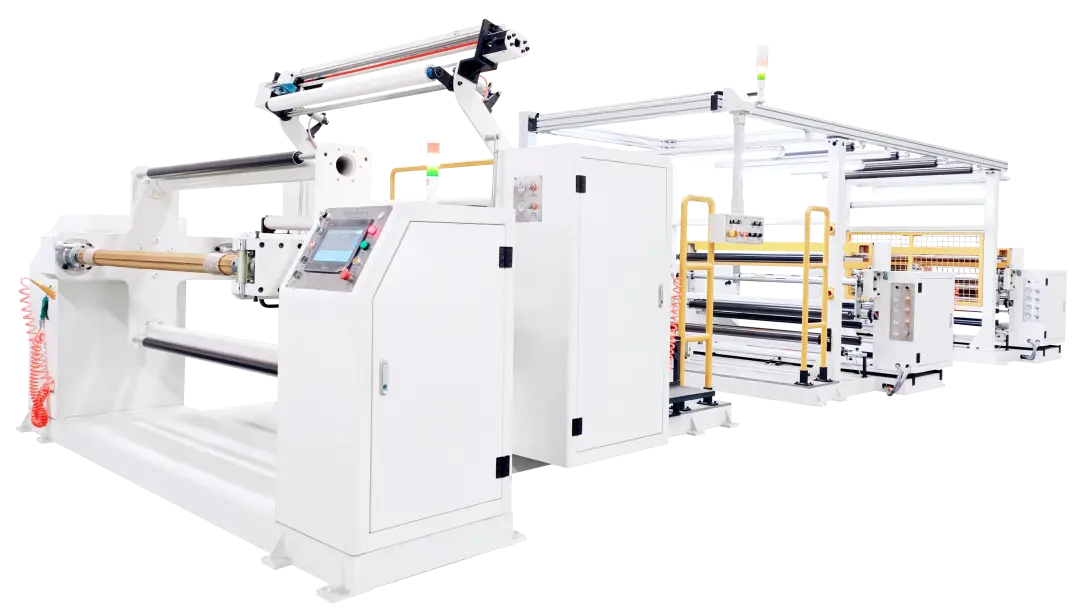

Double Layer Nonwoven Laminating Machine is specialized equipment used to bond two layers of nonwoven fabric together, enhancing the material’s strength and functionality for various applications.

| Mechanical Speed: | 80m/min |

| Normal Speed: | Hot Air Nonwoven 60m/min; Spunbond Nonwoven 70m/min |

| Finished Product Width: | 600mm |

| Effictive Embossing Width: | 650mm |

| Unwinding Diameter: | Φ 1200mm |

| Winding Diameter: | Φ 800mm |

| Max Design Speed: | 100m/min |

| Normal Speed: | 90m/min |

| Unwinding Diameter: | 1st: Φ1000mm; 2nd: Φ900mm |

| Winding Diameter: | Φ900mm |

If you know what you want to produce but are unsure which technology you need, we will be happy to advise you. We will guide you to the right component or line.

Nonwoven fabric provides a soft and breathable surface, ensuring comfort and reducing skin irritation.

Non-woven fabric provides high absorbency and leak protection, ensuring user comfort and dignity.

Its high absorbency and softness enhance comfort and hygiene for users.

Non-woven fabric offers high absorbency and protection for bedridden patients or pets.

It provides a disposable, hygienic solution to maintain cleanliness in medical and cleanroom environments.

AZX has more than ten years of R&D, production and sales experience.

Over 300 AZX non woven production lines have been already installed worldwide.

AZX has a 10,000 square meter workshop.

AZX controls over 20 core technologies and technical patents of non woven machines.

AZX non woven machines have already been provided to over 30 countries and regions.

AZX remote assistance system can help you find and deal with problems in time.

We’ve got you covered with a free non-woven machines catalog.